- Ring blower features high reliability.

- Has unique tolerance in high pressure.

- Operating temperature: -20 degree to +40 degree.

- Relative humidity: below 80%

- Altitude: < or = 1000m.

- When circumstance suddenly changes, blowers can still run safely and smoothly.

- Because of its simple design, it needs almost no maintenance.

- With fine-cooling outer bearing, the blower also has the following strong point: 1) High Pressure 2) The bearing operates with low temperature 3) The lubrication gives extra durability in use 4) Easy Maintenance.

Can be used in both supply and exhaust system applicable in paper cutting, oxygen increasing/decreasing, filter shaping, mist drying, water treating, printing, molding, material feeding/collecting, powder/liquid filing, welding equipment, filming machinery, paper feeding, clothes drying, air duct removing, bottle drying, air conveying, etc.

- Don’t touch the housing or motor or inlet or outlet in case of heat and electricity injury.

- Protection Device is required if installed in open air, long time exposure with the sun, rain corrosion, snow or duct.

- Don’t use in acid or soda or inflammable air environment in case of danger.

- If used in environment full of duct, particle or fibre material, filtering device should be added and periodic cleaning is required.

- Don’t use in close are or box.

- Can also be used in area with good ventilation to cool the temperature.

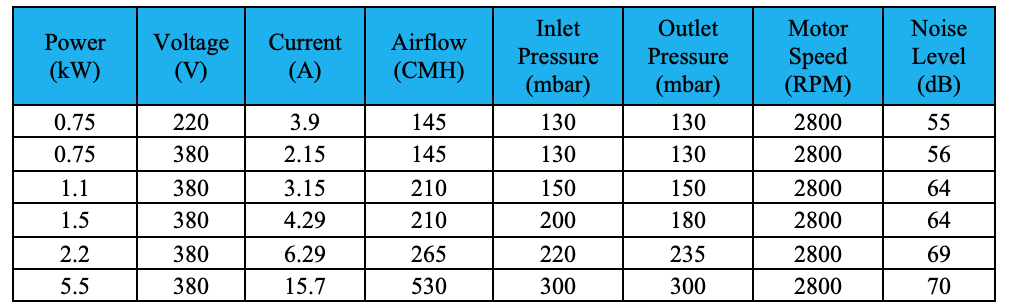

- Motor load current will change according to the pressure.

- Overload protection switch should be added and used in full rated current to avoid burning out of the motor winding.

- Use tube or duct of the same size as inlet or outlet for better performance.

- Power must be disconnected before maintenance.

- Ground wire has to be connected.

- Periodically clean the surface and inner part.

- Clean the duct or otherwise heat radiation performance will decrease which can lead to temperature rises and vibration.

- Bearing, oil seal and silencer should be replaced correspondingly.

- Before starting – a) check if wire is correctly connected, b) check if the power supply is the same as blower’s parameter c) check if the screws are tightly fixed to the connection bar.

- Motor protection during operation – a) avoid incorrect current setting and set protection device to correct setting b) when started frequently within short period, use solenoid valve or air operated valve to switch and c) during pressure difference or overload, increase the size of inlet, outlet tube and safety valve as well.

- Clean the filter if necessary.

- Overheating – a) when environmental or inlet temperature too high then working pressure becomes greater than the rated value, use cool air to fix the situations.