- The impeller is of firm paddle-wheel design.

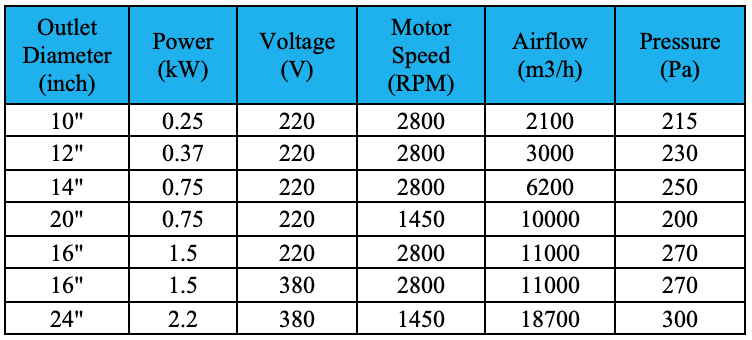

- According to the user requirements, the fans can be divided into 3 types ; wall type, pipeline types and stand types.

- The motors of the fans is of explosion-proof type and the insulation class is F.

- Due to the above features, the fans can be used in relatively high humidity environment.

- The temperature of the environment should not exceed 60’C.

- The wall type fans are commonly used in the exhaust system.

- The pipeline types are used for ventilation system in industrial and mining industries and commercial buildings.

- The fans can be also used in manufacturing operations of chemicals, foods and pharmaceutical, power plants, grain storage, tobacco smoke extraction, and other workplaces.

- It can also be used for ventilation system in air-conditioning system.

- Before starting, check the supply voltage (tolerance + and – 10%) and connected to the ground properly to ensure the safety.

- After 4000 hours of operation, the fan should be cleaned and bearing must be replaced.

- The fan should not be placed or used in a strong corrosive gaseous environment, so as not to damage the motor insulation and other parts.

- The product is restricted in high ambient temperature as it causes the capacitor or wire box to melt and burn which in turn results in damage to the fan.